When a winter storm slammed 34 states with a destructive mix of ice, heavy snow and freezing rain late last month, David Dellal stood ready with a product that could help.

In 2017, Dellal, then a mechanical engineering student at the Massachusetts Institute of Technology, helped create a sustainable, cost-effective system for deicing roofs and gutters as part of a class capstone project. The system uses sensors and real-time weather data to monitor for ice and, when it detects it, releases a water-based, non-toxic fluid, melting the ice before it can become a hazard.

Early on, the students knew that the system could help fill a new space in the deicing market, launching a startup called Floe to continue the effort.

But they needed to find a way to turn their concept from a prototype to an actual product.

“We’re engineers by training — mechanical engineers, electrical engineers — we obviously know how to do some form of engineering,” Dellal, who serves as a co-founder and CEO of Floe, said in an interview. “But when it’s about quality control and making sure these things live up in the field and also thinking about a full product lifecycle, we’d never really had hands-on experience with that before.”

It didn’t take too long for Floe to find a group that could help. The team was connected with FORGE, a Somerville, Mass.-based nonprofit that helps startups and innovation-oriented companies navigate the tricky path from prototype to full-scale production.

FORGE, Dellal says, was crucial to providing early developmental advice. The organization also provided funding, giving Floe some financial support after the startup won an audience choice award at a manufacturing and innovation showcase in 2020.

So when Dellal and another Floe executive moved to Connecticut to start their engineering Ph.D.s at Yale, the startup CEO was worried that leaving Massachusetts and FORGE would become a setback for the business.

Fate, however, had different plans. FORGE announced a move into Connecticut in 2023, spreading its work helping startups and other companies further into New England. In the years since, the organization has partnered with the state’s Office of Manufacturing to support startups in an effort to fix a trio of connected issues: boosting Connecticut’s manufacturing industry among young workers, helping provide advice and support to innovators working with emerging technologies, and providing funding to early stage CT-based startups that often struggle to access capital and make the leap into local manufacturing and, ideally, full-scale production.

In doing so, FORGE has become a key part of the state’s effort to reignite and develop its manufacturing sector, a significant part of the Connecticut economy that has struggled in recent years.

And by giving money directly to early-stage entrepreneurs, the accelerator is helping young companies navigate a crucial stage that many businesses don’t survive.

“A lack of access has nothing to do with having the right fundamentals to be scalable,” says Laura Teicher, the executive director and president of FORGE. “That’s a huge part of what we’re trying to solve.”

Helping innovators overcome the ‘valley of death‘

FORGE first emerged in the mid-2010s in the hopes of addressing a significant yet somewhat overlooked problem: a lack of funding for physical product developers.

Software companies and tech platforms often get the most attention when it comes to funding from venture capital firms and angel investors looking to find emerging talent. “Hardtech” companies focused on physical products, however, face more of a struggle when it comes to transitioning from early stage prototypes to commercial products.

The resulting gap in funding for these hardtech companies leads to what is known as the “Valley of Death,” the period where a company has developed a viable product, but lacks the money, manufacturing support and supply chain to pivot into consistently making it.

Overcoming this gap is a critical moment for a business, but few organizations focus on helping companies navigate it. By offering free support to entrepreneurs with already fleshed-out product ideas, from advice and networking opportunities to assistance finding local manufacturers and funders, FORGE seeks to change that.

While the organization is based in Massachusetts, Teicher and other FORGE leaders say that expanding into Connecticut was a no-brainer.

“One thing that was really appealing to us about Connecticut was the percent of the manufacturing base that is advanced manufacturing,” said Teicher. “The existing base of established manufacturers and suppliers is proportionally more advanced manufacturing than any other region we’ve operated in.”

Since launching its Connecticut branch in New Haven three years ago, the organization has also offered an additional resource to CT-based companies: money.

After offering smaller grant awards in its first year in the state, in 2024, FORGE announced that it was working with the Connecticut Office of Manufacturing, a subsection of the state Department of Economic and Community Development, to establish a more impactful effort. The organization received more than $800,000 from the state’s Manufacturing Innovation Fund to cover its work, using a significant portion of that money to launch the Connecticut Product Development Grant Program, a competitive fund that provides money to help local startups.

The program offers grants between $30,000 and $100,000 to support local companies as they transition into production and local manufacturing. The grants require a detailed application outlining how much a company needs and how the money would be spent. The funds are non-dilutive, meaning that recipients don’t have to give up any equity in their business to receive the money.

“When they get this bridge funding, this gap funding that the MIF has provided us with, they are actually producing a product. They’re getting customers, and then they’re becoming more attractive to the ventures and angel groups of the world,” Adam Rodrigues, FORGE’s vice president, told the Connecticut Mirror in a recent interview. “And that’s how they’re really getting to that long term production and ultimately becoming the next generation of Connecticut manufacturers.”

‘The opportunity to have funding accessible at these times is critical’

Since the product development grant award program launched in Connecticut, FORGE says that it has provided more than $460,000 in funding to 16 grant winners. While the majority of the grant program is funded through the MIF contract, FORGE also received additional support from private funders and CTNext, a now-defunct organization once tasked with supporting entrepreneurship and innovation in the state.

Jeremy Bronen, founder of SedMed, a Milford-based medical device startup and 2025 product development grant award winner, says that the money has been transformative. The company, which sells a toilet lift device that helps elderly and disabled individuals and the health care workers who support them, won $50,000 to help develop a new generation product.

“Every dollar you’re spending in these moments, in these days, matters,” Bronen said. “For us and for other companies that are younger and trying to find their way, having the opportunity to have funding accessible at these times is critical.”

Bronen, a Woodbridge native, first worked on the device that would lead to SedMed while he was a student at the University of Connecticut. He connected with FORGE at a demo day event and quickly fell into networking through the organization. In addition to last year’s award, SedMed previously received a $20,000 “cleantech” grant from FORGE in 2023. Working with FORGE also helped the young company meet an investor.

“We’re extremely grateful for the opportunities FORGE has presented,” Bronen said. “It 100% made a huge difference for us.”

Those working for FORGE say that its contributions to Connecticut manufacturing go beyond the no-strings-attached cash. “We’ve been able to work with over 160 emerging Connecticut hardtech innovators, and we’ve made over 500 connections between these innovators and manufacturers,” Rodrigues said.

And those connections could prove significant in Connecticut, a state where manufacturing has long been a major economic driver, albeit one that has faced recent headwinds. There are more than 4,000 manufacturing companies in the state, according to a 2025 survey conducted by the Connecticut Business and Industry Association. In total, the sector employs some 153,600 people, and it is still a significant part of the Connecticut economy, accounting for 11.6% of the state’s GDP in 2024.

But finding enough workers to support the sector has been a particular concern, with the state launching various efforts to develop its manufacturing workforce as it tries to recover from the job losses of recent decades. The existence of FORGE could help the industry grow further by providing a launch pad for new companies and a spotlight on innovators who could become important figures in the state’s manufacturing sector in the future.

Building new momentum for Connecticut manufacturing

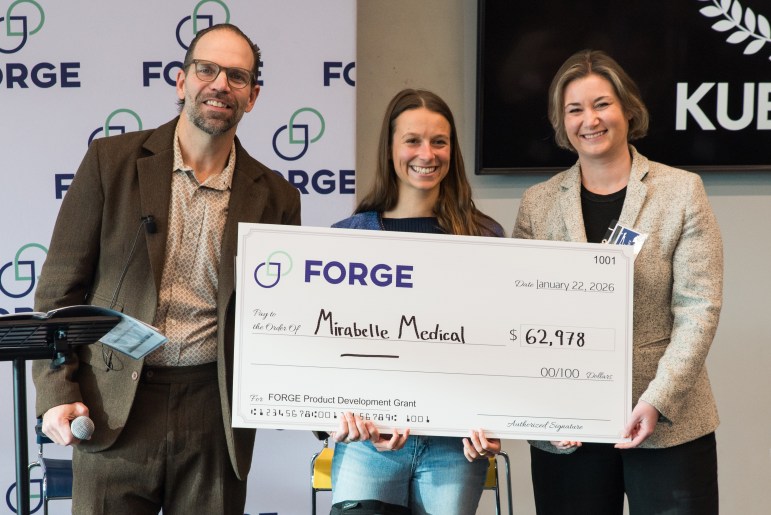

Last month, local manufacturers, startup founders, investors, suppliers and members of the state’s business community gathered at Kubtec, a Stratford-based medical imaging company, to celebrate the latest round of product development grant award winners.

As people settled into a room on the second floor, they were greeted by a monitor displaying a quote from Jensen Huang, president and CEO of Nvidia, a leading developer of graphics processing technology and currently the world’s largest company: “My will to survive exceeds everybody else’s will to kill me.”

FORGE announced that three companies won awards in its latest round, the most competitive to this point. In total, the organization handed out more than $220,000, including a $100,000 grand prize, FORGE’s largest product development grant award to date. The winning companies have also been connected to local manufacturers, allowing product development to happen in the state.

The grand prize winner, Hera Materials, seeks to replace single-use plastics with a specially developed biodegradable paper film. The award will help the company as it sets up a facility in Connecticut.

Tara Gensure, an engineer for the company who accepted the award, told the Connecticut Mirror that Connecticut’s renewed focus on manufacturing encouraged Hera Materials to set up in the state.

“Originally, we were applying for grants in Massachusetts, and we found out that Connecticut’s more of a manufacturing state,” she said. “We were very interested in making connections and finding some money as well.”

Clémence Bruguier, the cofounder of Mirabelle Medical, a New Haven breast care company that won roughly $63,000, said that the grant award will help the company reach the next level.

“We’ve been at this for like, a year and six months, so the grants are actually life changing,” said Bruguier, who founded the company with her partner in 2024. The company has designed an affordable tool that helps women check their breasts for lumps between mammograms and currently offers the product for pre-order on its website.

Bruguier said the grant will help Mirabelle Medical fulfill its preorders with the help of a local manufacturer.

The manufacturing support, she says, will be especially helpful. “It’s so much better in terms of sustainability, not shipping your products all the way back to China,” she said, noting that younger companies often default to producing products overseas. “Like you’re literally manufacturing it an hour away from your house.”

During the event, Bruguier was approached by members of the Connecticut Small Business Development Center interested in discussing additional ways to help.

Providing that combination of funding, exposure, and networking opportunities, Teicher says, is crucial. The awards are “a great example of bringing all these different communities together and injecting capital,” she said. “We’re helping more of these companies through an unnecessary valley of death that we believe often has to do with a lack of access, not a lack of strength.”

Dellal, the Floe co-founder, agrees. He has kept in touch with FORGE over the years, continuing to use the organization’s resources as the business expanded into New Haven. When the accelerator launched the Connecticut Product Development Grant Program in 2024, Floe was the first grant winner, taking home $30,000.

FORGE, Dellal says, “fills a very unique niche in the ecosystem.”

“A lot of folks don’t really think about funding unless you’ve built a manufacturing line before,” he said. “There’s very few opportunities to do debt financing or get a loan, it’s very difficult to get that same level of cash.”

In the coming months, FORGE hopes to continue its work. The organization plans to distribute at least another $50,000 in product development grants and will keep working with startups and entrepreneurs to turn product development ideas into prototypes and actual products. And as the grant award applications increase, the organization says that it is showing that there is an appetite for new manufacturing in Connecticut.

“There’s a momentum here, there is this manufacturing and innovation ecosystem that wants to break out, wants to come to life,” Rodrigues said. “That’s what we’re here to support.”